What is the Advantage of Inkjet Marking Machine?

Advantage of Inkjet Marking Machine

One of the advantages of an inkjet marking machine is its automation. A DOD printer can implement date or change numbers without the assistance of a human operator. This type of marking machine can be used in a variety of industrial activities, such as the automotive and medical industries. The advantages of an inkjet marking system are wide application and quick programming. However, it has some drawbacks as well.

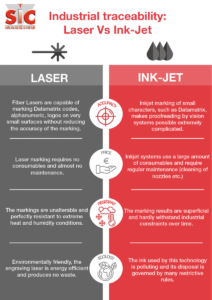

For a wide range of industrial marking applications, an inkjet marking system can be an ideal choice. These printers are comparatively cheaper than laser marking machines, and can apply a number of different applications. These printers are more versatile than laser-based systems, as they can mark a wide variety of materials. While they are cheaper than laser-based marking systems, their quality is not as high.

In addition to a lower price, inkjet marking machine are easier to use. Because they are computer controlled, they require fewer maintenance costs. They are also more precise, which means that a higher quality imprint can be achieved. The advantages of an inkjet-based marking system include: productivity; reduced maintenance time; and greater speed. Aside from these benefits, inkjet-based marking machines are ideal for a wide range of industrial marking applications.

What is the Advantage of Inkjet Marking Machine?

The main disadvantage of an inkjet-based marking system is the need to manually adjust the ink. Unlike a laser marking system, an inkjet-based marking system does not require any manual adjustments. It does require more work, since more variables need to be adjusted. For instance, the temperature of the ink jet, the pressure of the jet, the amount of time to focus on one mark, and the time between printing each mark can all affect the quality of the mark. Nonetheless, inkjet-based marking systems are more efficient than laser-based systems in many industrial applications.

A laser-based marking system uses a high-intensity beam and is subject to chemical pollution. An ink-jet-based marking system does not cause any environmental pollution, but may damage the object. Whether you need a permanent mark, you can choose between an inkjet-based and laser-based system. You can select the type that best suits your needs. You can find out more about both options in our comparison table.

When choosing an inkjet-based marking system, make sure to consider the advantages and disadvantages of both. Compared to laser marking, inkjet-based systems are more flexible and allow you to make adjustments with ease. This makes inkjet-based marking machines the perfect solution for industrial applications. They are easy to use and will save you money in the long run. But be sure to consider the advantages and disadvantages of inkjet-based printing.